Biomaster: A Game-Changer in Antimicrobial Packaging

When it comes to packaging, the integration of antimicrobial technology has become extremely important. At the forefront is Biomaster antimicrobial technology, a versatile solution designed to inhibit the growth of a broad spectrum of microorganisms. With its numerous applications, Biomaster is reshaping various industries by providing antimicrobial product protection to packaging.

Biomaster antimicrobial technology is a proven and effective solution, addressing the pressing need for microbial control in and on packaging. It offers robust product protection against microbial contamination in a diverse range of industries, from healthcare and food manufacturing to electronics.

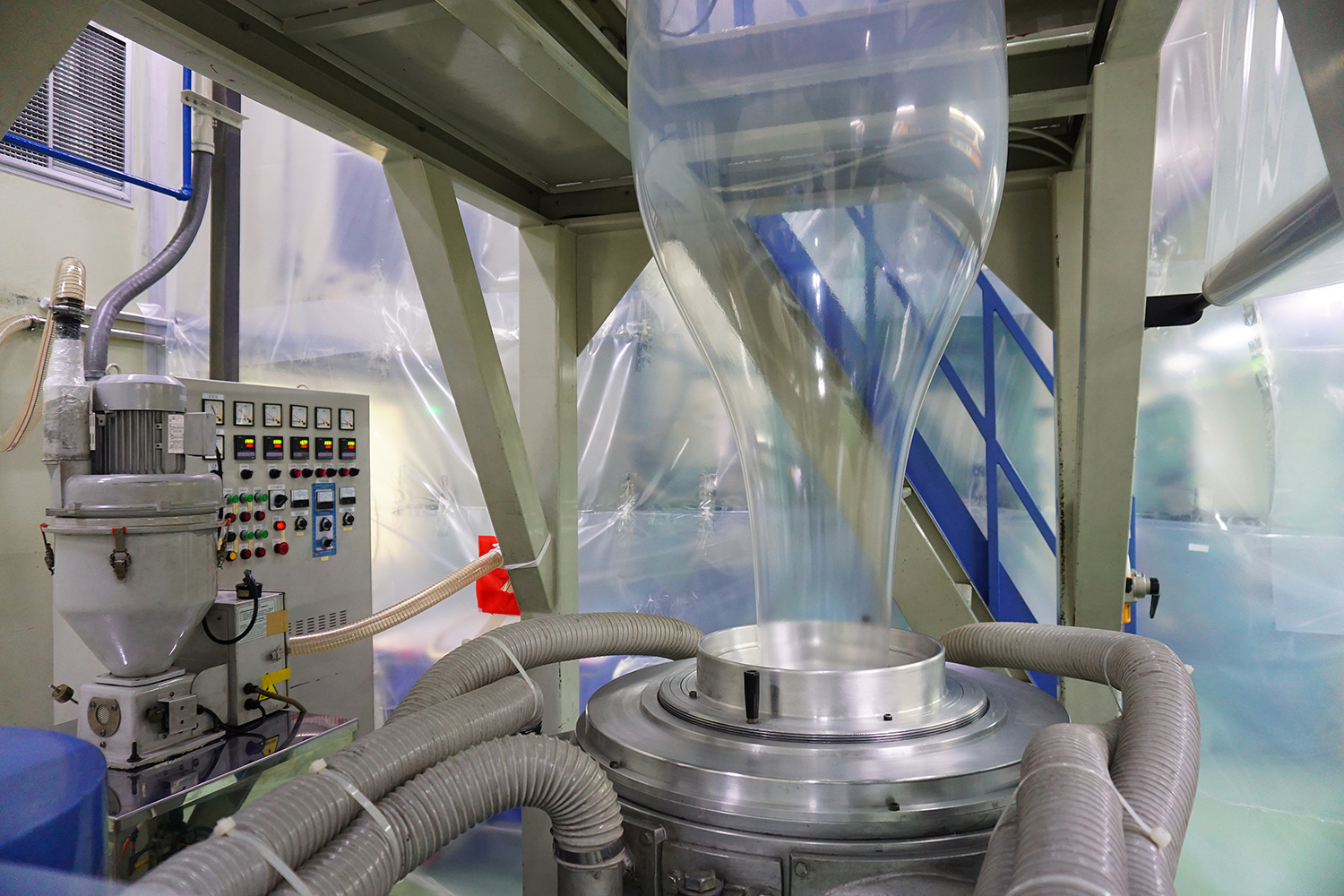

Applications in Plastic Films

The seamless fusion of innovative antimicrobial technology with the versatility of plastic films has ushered in a new era of product protection and longevity.

Manufacturers, recognising the potential of Biomaster, have embraced this technology to create plastic films with enhanced antimicrobial properties. The incorporation of Biomaster into plastic films serves as a proactive shield against the proliferation of harmful microorganisms, contributing significantly to the hygiene of the packaging.

Industries, particularly those involved in healthcare and electronics packaging, have experienced substantial benefits from this ground-breaking approach. In healthcare, Biomaster-infused plastic films play a crucial role in reducing the microbial load on medical supplies and equipment.

With electronics packaging, where sensitive components and devices require protection from environmental factors, Biomaster technology adds an extra layer of product protection. The antimicrobial properties embedded in the plastic films act as a shield, safeguarding electronic equipment against microbes during storage and transportation. This helps minimise the risk of performance degradation caused by microbial-induced damage.

The benefits of Biomaster-infused plastic films extend beyond just product protection; they contribute to the overall sustainability and efficiency of the supply chain. By helping reduce the likelihood of microbial product degradation, these protected plastic films help minimise product waste and associated economic losses.

The marriage of Biomaster technology with plastic films is a game-changer for the packaging sector. It actively participates in the preservation of packaging quality and hygiene. As industries continue to prioritise these crucial factors, Biomaster-infused plastic films emerge as a strategic and indispensable component in the evolution of modern packaging practices.

Benefits in Paper and Cardboard Packaging

Biomaster technology seamlessly extends to paper and cardboard packaging materials, bringing about a significant enhancement in antimicrobial product protection. Biomaster provides an additional layer of product protection against microbial contamination, addressing the diverse needs of industries.

In the consumer goods sector, where products ranging from cosmetics to household items are packaged in paper and cardboard, Biomaster technology plays a crucial role in preserving surface hygiene.

Beyond the direct benefits of hygiene, Biomaster's presence in paper and cardboard packaging materials aligns with broader sustainability goals.

The integration of Biomaster into paper and cardboard packaging materials, therefore, represents a multifaceted approach to addressing the unique challenges of diverse industries. Its application goes beyond a superficial layer of product protection; it becomes an active participant in maintaining the quality and sustainability of packaged products. As industries continue to emphasise these critical aspects, Biomaster-infused paper and cardboard packaging emerges as an indispensable and versatile solution for a wide range of applications.

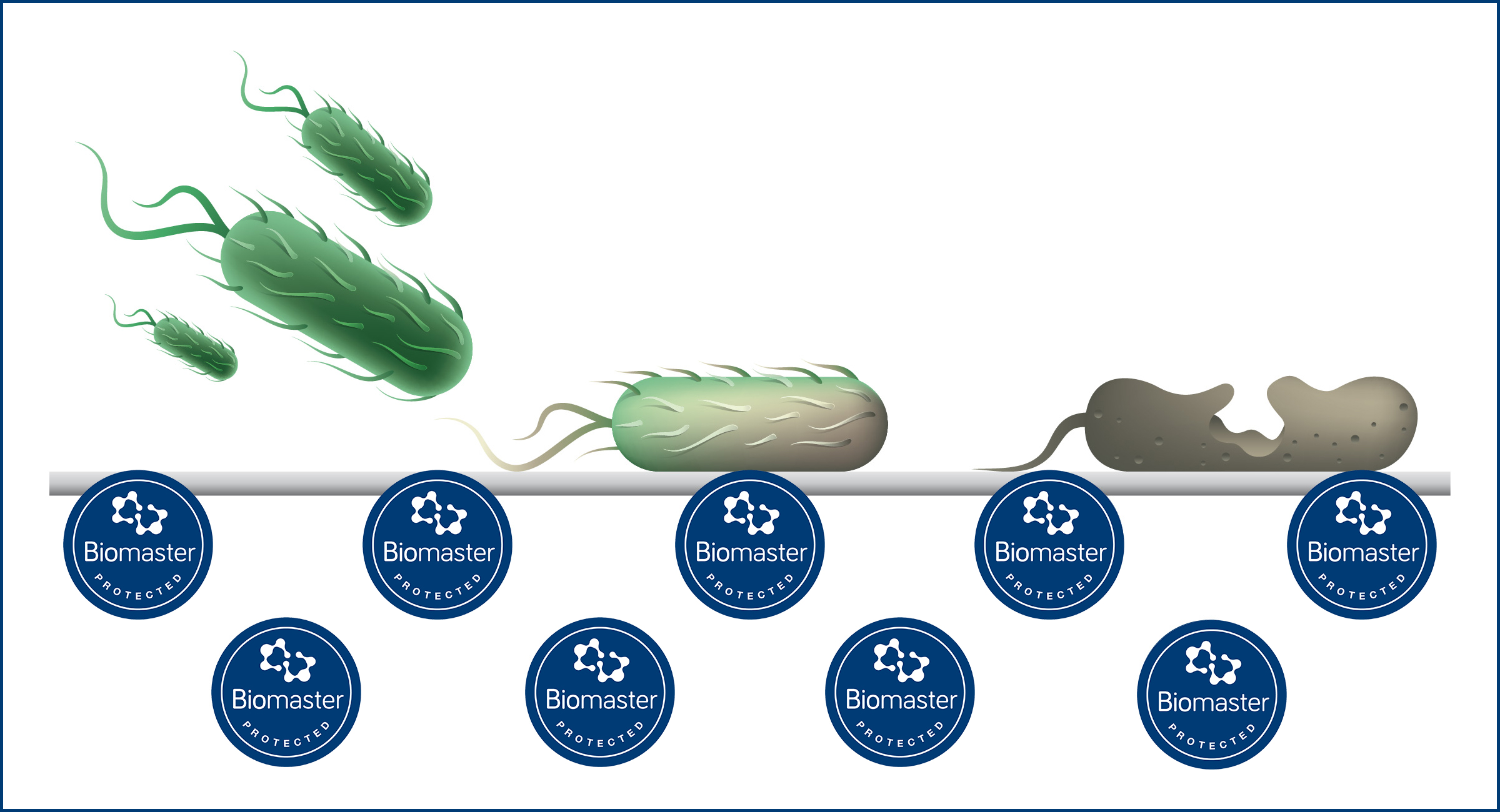

Mechanism of Action

Biomaster's efficacy is rooted in its sophisticated and precise mechanism of action, which involves disrupting microbial cell membranes and inhibiting crucial enzyme activity. This nuanced approach is pivotal across various industries, offering effective product protection against degradation caused by harmful microorganisms.

The disruption of microbial cell membranes is a key aspect of Biomaster's mechanism of action. Microbial cell membranes are vital structures that maintain the integrity of microorganisms. By interfering with and destabilising these membranes. Biomaster effectively weakens the structural integrity of the targeted microorganisms, rendering them unable to function and reproduce. This disruption is a formidable defence, preventing the growth and proliferation of bacteria, fungi, and other microbes that could compromise the quality of packaged products.

In addition to membrane disruption, Biomaster also excels in inhibiting crucial enzyme activity within microorganisms. Enzymes are essential for various biological processes within cells, and by inhibiting these enzymes, Biomaster disrupts the fundamental biochemical pathways necessary for microbial survival and growth. This dual-action mechanism significantly enhances the antimicrobial efficacy of Biomaster, providing comprehensive and robust product protection against a wide spectrum of microorganisms.

What sets Biomaster apart is its suitability in a wide range of materials, making it a versatile solution for diverse packaging needs, and much more. The ability of Biomaster to tailor its application in a wide range of materials ensures that its antimicrobial properties are optimised for each application. Whether incorporated into plastic films, paper, cardboard, or other packaging materials, Biomaster demonstrates consistent effectiveness, addressing the unique challenges posed by different industries.

Essentially, Biomaster's mechanism of action represents a sophisticated and adaptable solution that goes beyond conventional antimicrobial approaches. Its ability to disrupt cell membranes and inhibit crucial enzyme activity serves as a cornerstone in the preservation of product integrity across diverse industries, making Biomaster a reliable and versatile ally in the ongoing evolution of antimicrobial packaging technology.

Conclusion

The integration of Biomaster antimicrobial technology into packaging materials revolutionises how we protect packaging and products across various sectors. Whether in healthcare, electronics, food & drink or consumer goods, the role of antimicrobial packaging is indispensable. The future of packaging is not just about containment; it's about preserving the integrity of packaging across the spectrum. Biomaster, with its versatility and efficacy, is at the forefront of this transformative journey, ensuring a more hygienic future for a diverse range of industries.

What Next?

🔗 Follow us on Social Media, here is our LINK TREE

✉️ See how our additive technology can benefit your business by CONTACTING US

🦠 Find out more about Biomaster Antimicrobial Technology HERE

🎥 Watch our video on how Biomaster works WATCH NOW

📰 Subscribe to our Newsletter - SUBSCRIBE

← Back to blog