Plastics in Modern Architecture and Construction

Plastics have become indispensable in contemporary architecture and construction due to their exceptional versatility, durability, and cost-effectiveness. Their unique properties and wide range of applications have positioned them as vital components in modern building design and construction. Unlike traditional materials (wood, metal, and concrete - which all have their place) plastics offer a remarkable flexibility in terms of design possibilities, allowing architects and builders to push the boundaries of creativity and innovation. Their ability to be moulded into various shapes and sizes enables the creation of complex architectural forms and intricate details that are often unachievable with conventional materials.

Durability and Longevity

Plastics are prized in contemporary architecture and construction for their innate resistance to corrosion, weathering, and chemical degradation, rendering them exceptionally durable for long-term applications. This durability is pivotal in ensuring that plastic components retain their structural integrity and aesthetic appeal over extended periods, thereby minimising the necessity for frequent repairs or replacements. Polyvinyl chloride (PVC) pipes and fittings as an example stand as a testament to this resilience, capable of enduring decades without substantial deterioration. This longevity makes them a preferred choice for plumbing and water distribution systems in diverse environments, including residential, commercial, and industrial buildings.

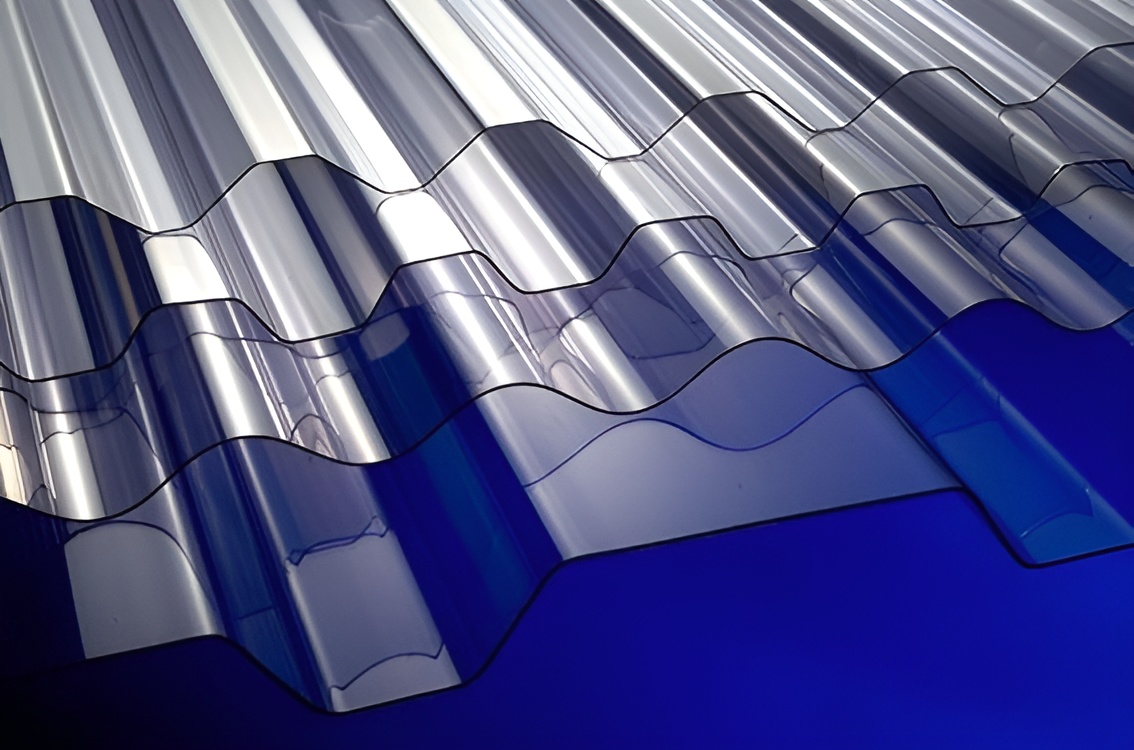

The robust nature of plastics extends beyond PVC to encompass a variety of materials used in construction. High-density polyethylene (HDPE), renowned for its strength and resistance to chemical corrosion, serves as another prime example. HDPE pipes are extensively employed in water supply systems and underground drainage due to their ability to withstand aggressive environmental conditions and soil chemicals. Similarly, polycarbonate, recognised for its impact resistance and UV stability, is favoured for applications such as skylights and roofing panels where durability and weather resistance are paramount.

Moreover, the durability of plastics contributes significantly to sustainable building practices by reducing the environmental impact associated with material production and disposal. By requiring fewer replacements and repairs over their lifespan, plastics help to conserve resources and minimise construction waste. This aspect aligns with the principles of circular economy, wherein materials are utilised efficiently and retained in use for as long as possible.

In essence, the exceptional durability of plastics not only enhances the reliability and longevity of construction projects but also supports sustainable development goals by promoting resource efficiency and reducing environmental footprint. As such, their widespread adoption continues to redefine modern construction practices, offering versatile solutions that meet the evolving demands of architectural design and infrastructure development.

Lightweight

Compared to traditional construction materials such as metal and concrete, plastics offer a notable advantage due to their significantly lighter weight. This characteristic not only simplifies transportation and installation processes but also contributes to substantial cost savings in labour and shorter construction timelines.

The lightweight nature of plastics enhances the structural efficiency of buildings by facilitating innovative architectural designs that were previously constrained by the weight limitations of traditional materials. Architects and designers can explore expansive roof spans, intricate façades, and daring structural configurations without compromising on safety or performance. For instance, the integration of lightweight polycarbonate panels in roofing systems not only reduces the overall load on the building's framework but also enhances natural light penetration into interior spaces. This dual benefit not only promotes a more sustainable use of energy but also creates brighter more inviting environments that enhance occupant comfort.

Furthermore, the use of lightweight plastics in construction contributes to the overall sustainability of buildings by minimising embodied energy and reducing carbon emissions associated with transportation. Lower transportation weights translate to reduced fuel consumption and environmental impact during the supply chain, aligning with global efforts to mitigate climate change and promote greener building practices. Additionally, the ease of handling lightweight plastics on-site reduces the risk of workplace injuries and improves overall construction safety, further underscoring their role as preferred materials in modern building projects.

Insulation Properties

Plastics play a crucial role in enhancing both thermal and acoustic insulation in buildings, thereby significantly contributing to energy efficiency and improving occupant comfort. Their ability to effectively reduce heat transfer helps maintain stable indoor temperatures throughout the year, which in turn reduces reliance on mechanical heating and cooling systems, leading to substantial energy cost savings.

Plastics are a preferred insulation material for various building components including walls, roofs, and floors due to their low thermal conductivity. This characteristic ensures minimal heat loss during colder seasons and mitigates heat gain during warmer months, thus creating a more comfortable indoor environment while reducing the building's overall energy consumption. By limiting thermal bridging and enhancing the building envelope's thermal performance, Plastics contribute to achieving higher energy efficiency ratings and compliance with stringent building codes and standards.

The acoustic properties of plastics, effectively dampen sound transmission between interior spaces. This acoustic insulation capability helps create quieter and more conducive indoor environments, particularly in residential, educational, and healthcare settings where noise control is essential for occupant well-being and productivity.

The adoption of plastic-based insulation solutions not only enhances building performance but also supports sustainable construction practices by reducing carbon emissions associated with heating and cooling operations. By minimising energy demand and improving indoor comfort levels, plastics contribute to a greener built environment and align with global efforts towards reducing the environmental impact of buildings. As such, their integration into construction projects not only meets functional requirements but also advances the goals of energy efficiency, environmental sustainability, and enhanced occupant comfort.

Versatility

Plastics empower architects and builders with unprecedented freedom in design, facilitating innovative possibilities and intricate architectural forms that are often unattainable with conventional materials. This versatility encourages exploration of novel design solutions, pushing boundaries in architectural aesthetics and functionality.

Acrylic exemplifies this capability in its application for creating elaborate façade elements and decorative panels that elevate the visual appeal of buildings. Acrylic’s innate transparency and ease of fabrication make it a preferred choice in contemporary architectural designs. Architects leverage its optical clarity and ability to transmit light to create luminous, inviting spaces that blur the boundaries between indoors and outdoors. From sleek, modernist structures to historically inspired renovations, Acrylic allows for the realisation of diverse architectural visions that prioritise both form and function.

Beyond aesthetics, the moldability of plastics extend to enhancing structural efficiency and durability. Fiberglass-reinforced plastics (FRP), for instance, offer exceptional strength-to-weight ratios, making them ideal for constructing lightweight yet resilient architectural elements like domes, canopies, and cladding systems. This structural versatility not only supports innovative designs but also reduces construction complexity and costs associated with handling heavy traditional materials.

Moreover, the ability of plastics to resist corrosion and weathering ensures longevity in various environmental conditions, further enhancing their appeal in sustainable building practices. Materials like polyethylene (PE) and polypropylene (PP) are favoured for outdoor applications such as decking, fencing, and exterior furniture due to their durability and low maintenance requirements. Their resistance to moisture and UV radiation prolongs service life and minimises environmental impacts compared to wood and metal alternatives.

Cost-Effectiveness

The production and maintenance costs associated with plastic components are typically more economical compared to other materials, making plastics a compelling choice across diverse construction projects. This cost-effectiveness stems from several factors inherent to plastics, including their ease of manufacturing, lightweight nature, and durability, which collectively contribute to reduced production expenses and simplified installation processes.

Plastics offer significant long-term economic benefits due to their longevity and minimal maintenance requirements. Unlike materials prone to corrosion, such as metal, or susceptible to weathering, like wood, plastics exhibit inherent resistance to environmental degradation. This resilience translates into extended service life with minimal upkeep, thereby lowering lifecycle costs and enhancing overall cost-efficiency in construction applications.

For instance, in applications such as water and gas distribution networks, plastic pipes exemplify these economic advantages as they can withstand various chemical and environmental challenges without deterioration. Their low maintenance needs and long operational lifespan reduce the frequency of repairs and replacements, translating into substantial savings in both labour and material costs over the years.

Environmental Impact

Plastics also offer environmental benefits, particularly when it comes to sustainability and recyclability. Many plastic materials used in construction can be recycled and repurposed, reducing the demand for virgin raw materials and minimising waste. For example, recycled PVC can be used to produce new pipes, window frames, and flooring, contributing to a circular economy in the construction industry. Additionally, the lightweight nature of plastics reduces the carbon footprint associated with transportation and installation, further enhancing their environmental credentials.

Types of Plastics Used in Construction

Polyvinyl Chloride (PVC): PVC is known for its robustness and ease of installation, making it a popular choice for pipe & fittings, windows, and flooring. Its resistance to moisture and chemicals further enhances its suitability for these applications. The material's flame-retardant properties also make it a safe choice for electrical applications. PVC provides a durable and low-maintenance solutions for various building needs.

Polycarbonate: Polycarbonate is renowned for its high impact resistance and transparency, making it ideal for windows, skylights, roofing, and wall panelling. Its ability to withstand harsh weather conditions and provide natural light transmission makes it a valuable material in architectural design. Polycarbonate sheets are often used in sports facilities and commercial buildings where both strength and light transmission are required. The material's UV resistance and thermal stability further enhance its performance in outdoor applications.

Polyethylene: Polyethylene is widely used for insulation, vapor barriers, and geomembranes due to its flexibility and moisture resistance. Its versatility allows it to be used in various applications, from protecting buildings against moisture ingress to providing insulation for energy efficiency. High-density polyethylene (HDPE) is commonly used in geomembranes for landfill liners and pond linings, offering excellent chemical resistance and durability. Low-density polyethylene (LDPE), on the other hand, is used in vapor barriers and protective films, providing effective moisture control in building envelopes.

Acrylic: Acrylic is commonly used in lighting and signage due to its clarity and durability. It offers excellent optical properties and weather resistance, making it suitable for both indoor and outdoor applications. Acrylic's ability to maintain its transparency and appearance over time contributes to its popularity in architectural elements. Cast acrylic sheets are often used in glazing, skylights, and illuminated signs, providing long-lasting performance and aesthetic appeal. The material's ease of fabrication and wide range of colours and finishes make it a versatile choice for creative architectural applications.

Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS): EPS and XPS are commonly used as insulation materials in building envelopes. Both materials offer excellent thermal insulation properties, making them ideal for use in walls, roofs, and floors. EPS is typically used in external insulation and finishing systems (EIFS), providing a lightweight and effective insulation solution. XPS, with its higher compressive strength and moisture resistance, is often used in below-grade applications such as foundation walls and under concrete slabs.

High-Density Polyethylene (HDPE): HDPE is widely used in water and gas distribution systems due to its high strength, flexibility, and chemical resistance. The material's durability and low maintenance requirements make it a cost-effective solution for infrastructure projects. HDPE pipes are commonly used in water supply and sewer systems, offering a long service life and resistance to environmental stress cracking.

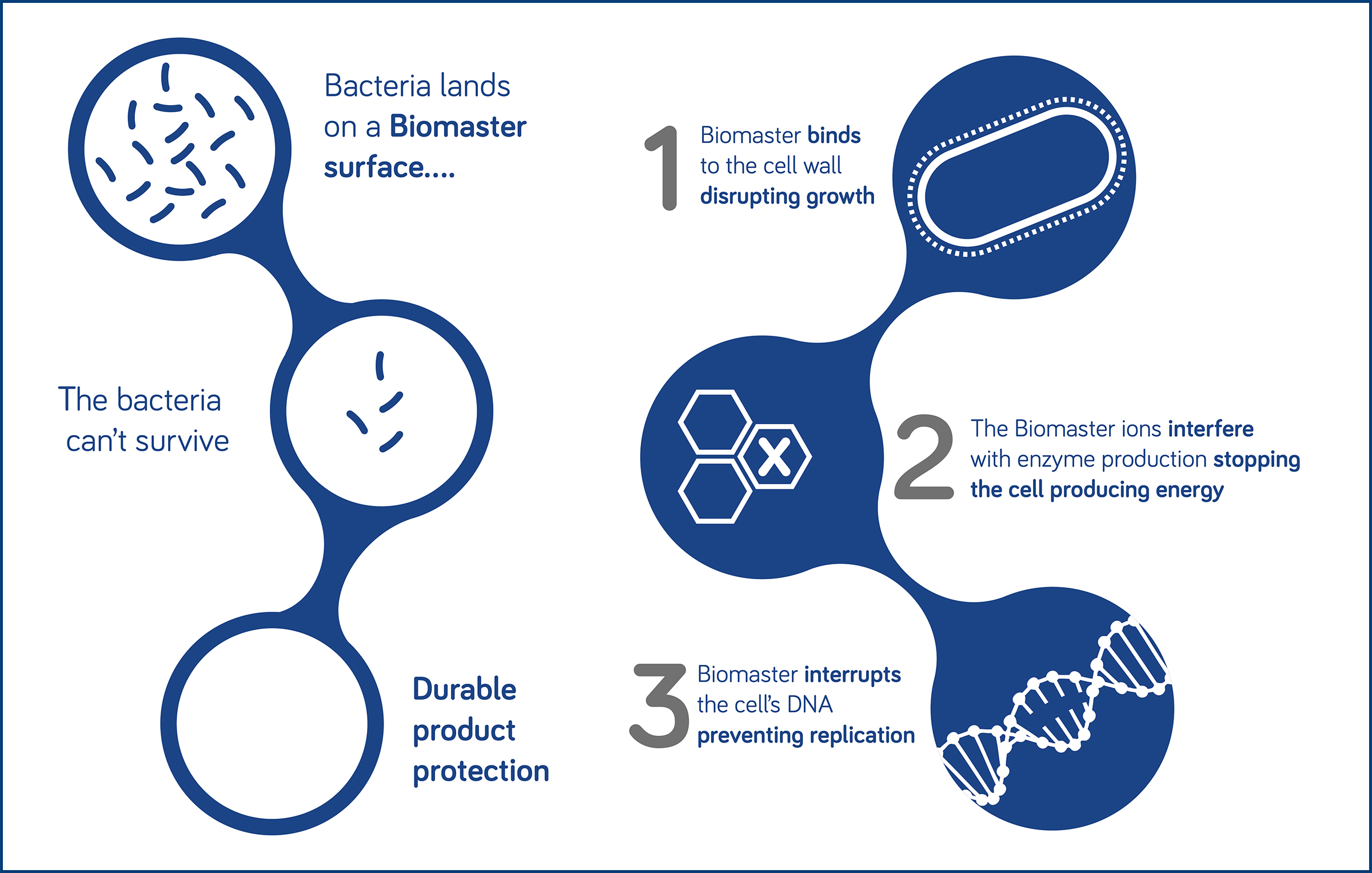

Antimicrobial Additives in Plastics

With growing concerns over hygiene, antimicrobial additives in plastics have become increasingly important. Antimicrobial additives inhibit the growth of microorganisms such as bacteria, mould, and fungi on the surface of plastic products, making them ideal for environments where hygiene is paramount, such as hospitals, schools, and food processing facilities.

Mechanisms of Antimicrobial Action

Antimicrobial additives can function through various mechanisms to inhibit microbial growth. Some additives, such as silver ions, disrupt the cellular processes of bacteria, leading to their inability to reproduce. Additionally, some antimicrobial agents work by creating a hostile environment for microbial growth, such as altering the pH or releasing reactive oxygen species.

Applications of Antimicrobial Plastics

Antimicrobial plastics have become essential in various industries where maintaining hygiene is critical. In healthcare settings, these specially treated plastics are widely used on surfaces in patient rooms and surgical suites. By reducing the presence of bacteria, fungi, and other microbes, antimicrobial plastics provide an additional layer of product protection, helping to reduce microbial loads on surfaces. This added product protection supports a more hygienic environment.

In educational environments like schools and childcare centres, antimicrobial plastics play a vital role in creating a more hygienic space. This is especially important in areas where environments are shared and multiple surfaces are contacted.

In the food processing industry, antimicrobial plastics are extremely important as hygiene is essential. By integrating antimicrobial plastics into food processing environments, companies can improve hygiene practices, enhance HACCP procedures and support compliance with health and safety standards.

Beyond these sectors, antimicrobial plastics are also beneficial in public transportation, hospitality, and fitness facilities—anywhere that high-touch surfaces are at risk of harbouring bacteria.

Brett Martin and Antimicrobial Technology

Brett Martin, a leading manufacturer of plastic sheets, drainage, and roof light products, has been at the forefront of incorporating advanced antimicrobial technology into their offerings. By partnering with Addmaster, a specialist in antimicrobial additives, Brett Martin has enhanced the hygiene of their products.

Antimicrobial Plastic Sheets

One of Brett Martin's key innovations is the production of antimicrobial plastic sheets treated with antimicrobial technology. These sheets offer continuous product protection against harmful microbes. This technology is particularly beneficial in environments where hygiene is critical.

The antimicrobial properties of these sheets are achieved through the incorporation of silver ions, which disrupt the cellular processes of bacteria and inhibit their growth. This continuous product protection ensures that surfaces remain cleaner for longer periods, complimenting existing cleaning and maintenance. The use of antimicrobial plastic sheets in hospital wall claddings, for example, can significantly support in improving hygiene in these environments.

Verimaster Security Technology

In addition to antimicrobial solutions, Brett Martin collaborates with Addmaster to incorporate Verimaster security technology into their cladding products. Verimaster adds a unique identifier into the product, ensuring authenticity and traceability. This technology is particularly beneficial for high-security applications and helps prevent counterfeit products from entering the market.

Product Authentication

Verimaster technology ensures product authentication, allowing customers to verify that they are receiving genuine Brett Martin products. This authentication maintains the quality and performance standards that Brett Martin is known for, providing peace of mind to customers.

The unique identifiers embedded in Verimaster-treated products can be scanned and verified using specialised equipment, ensuring that only genuine products are used in critical applications. This level of security is particularly important in industries where the use of counterfeit materials could have serious safety and legal implications.

Supply Chain Security

Verimaster enhances supply chain security by enabling traceability throughout the manufacturing and distribution process. This traceability helps prevent counterfeit products from entering the market and ensures that Brett Martin's products maintain their integrity and reliability.

By incorporating Verimaster technology, Brett Martin can track their products from production to installation, ensuring that they meet the highest standards of quality and performance. This traceability also helps identify and address any issues that may arise during the manufacturing and distribution process, improving overall product reliability and customer satisfaction.

Regulatory Compliance

Verimaster assists in meeting industry regulations and standards, providing an additional layer of safety and reliability. By incorporating Verimaster technology, Brett Martin demonstrates their commitment to quality and compliance, further solidifying their reputation as a trusted manufacturer of plastic products.

Compliance with industry regulations and standards is crucial in ensuring the safety and performance of construction materials. Verimaster technology helps Brett Martin meet these requirements by providing verifiable proof of product authenticity and traceability, enhancing the overall reliability of their products.

Conclusion

The use of plastics in architecture and construction continues to offer numerous advantages, driving innovation and efficiency in the industry. With the incorporation of antimicrobial additives and advanced security technologies, companies like Brett Martin are setting new benchmarks for hygiene and quality. As the demand for sustainable and resilient building materials grows, the role of plastics, enhanced with such cutting-edge technologies, will undoubtedly become even more significant in shaping the future of construction.

By leveraging the benefits of Biomaster antimicrobial additives and Verimaster security technology, Brett Martin not only enhances the performance and hygiene of their products but also addresses the evolving needs of the construction industry. These innovations reflect the ongoing commitment to quality, sustainability, and customer satisfaction, ensuring that plastics continue to play a vital role in modern architecture and construction.

You can find out more about Brett Martin and their products at https://www.brettmartin.com

You can find out more about Biomaster Antimicrobial Technology at https://www.addmaster.co.uk/technologies/biomaster

You can find out more about Verimaster Anti-Counterfeit Technology at https://www.addmaster.co.uk/technologies/verimaster

Further Reading

- Ahmed, A. (2018). Lightweight construction materials: properties and applications. Journal of Civil Engineering and Management, 24(6), 437-444.

- Bhutta, M. A. R., et al. (2011). Properties of plastic materials used in construction. Construction and Building Materials, 25(4), 2923-2930.

- Crawford, R. (2019). Building Materials: Impact on Performance. Elsevier.

- Eckert, R., et al. (2012). Durability and performance of acrylic materials in construction. Construction Materials, 3(2), 115-124.

- Gnip, I., et al. (2017). Insulation properties of plastics in building construction. Energy and Buildings, 155, 162-169.

- Papadopoulos, A. M. (2005). State of the art in thermal insulation materials and aims for future developments. Energy and Buildings, 37(1), 77-86, https://www.sciencedirect.com/science/article/abs/pii/S0378778804001641

- Hopewell, J., Dvorak, R., & Kosior, E. (2009). Plastics recycling: challenges and opportunities. Philosophical Transactions of the Royal Society B: Biological Sciences, 364(1526), 2115-2126, https://www.ncbi.nlm.nih.gov/pmc/articles/PMC2873020

- Bertolini, L., Elsener, B., Pedeferri, P., Polder, R. (2014). Corrosion of Steel in Concrete: Prevention, Diagnosis, Repair. Wiley-VCH Verlag GmbH & Co. KGaA, https://onlinelibrary.wiley.com/doi/book/10.1002/3527603379

- Kumar, R., & Anand, S. K. (1998). Significance of microbial biofilms in food industry: a review. International Journal of Food Microbiology, 42(1-2), 9-27, https://pubmed.ncbi.nlm.nih.gov/9706794

- Hopewell, J., Dvorak, R., & Kosior, E. (2009). Plastics recycling: challenges and opportunities. Philosophical Transactions of the Royal Society B: Biological Sciences, 364(1526), 2115-2126, https://royalsocietypublishing.org/doi/10.1098/rstb.2008.0311

What Next?

🔗 Follow us on Social Media, here is our LINK TREE

✉️ See how our additive technology can benefit your business by CONTACTING US

🦠 Find out more about Biomaster Antimicrobial Technology HERE

🎥 Watch our video on how Biomaster works WATCH NOW

📰 Subscribe to our Newsletter - SUBSCRIBE

← Back to blog