Biomaster technology provides antibacterial product protection solutions for fabrics from nursing uniforms to protective workwear, whilst also preventing malodour build-up, especially within sportswear.

Antimicrobial protection for textiles & fabrics

Biomaster antimicrobial technology is easily applied to textile manufacturing processes at any stage of production, helping fabric manufacturers to add antibacterial materials to their product range.

Without affecting the characteristics of the material, Biomaster provides durable and effective protection against both harmful and odour-causing bacteria

In order to confirm the efficacy of any antibacterial solution prior to production, our research department conducts exhaustive tests that simulate the actual usage of the article.

This means you can treat your t-shirts, bed sheets, cloths or any other type of textile with long-lasting, durable Biomaster antimicrobial protection.

Antimicrobial melt blend treatments

Biomaster can also be used in any fibre manufacturing process including PA (Nylon), PE (Polypropylene) PET (Polyethylene terephthalate) and PP (Polypropylene) melt blend textiles.

Low addition rates and high temperature stability make Biomaster masterbatches ideal for melt blended antibacterial fibre protection.

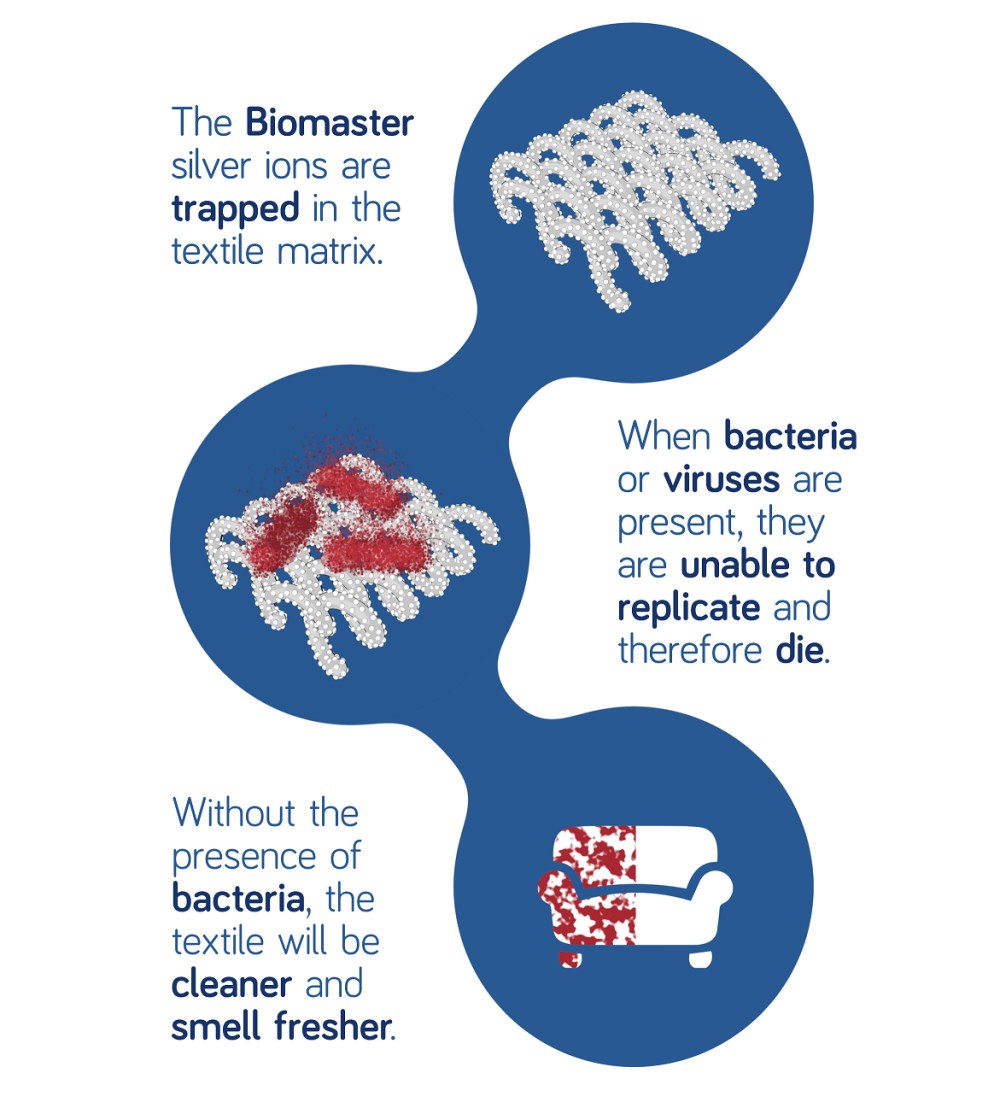

How Biomaster antimicrobial treated fabric works

Biomaster can be added at any stage of the manufacturing process and is available in masterbatch, liquid or powder formulations for plastics, textiles, paper and coatings.

When bacteria come into contact with a Biomaster protected surface, the active antimicrobial agent prevents them from growing, producing energy or replicating, inhibiting any further growth.

The controlled release of the active ingredient provides powerful, effective antimicrobial protection for the lifetime of the product.

Learn more about Biomaster, or get in touch for free, no-obligation advice on how to specify Biomaster antimicrobial fabric for your product range.

-

Solent Group

-

Composite Fibreglass Mouldings

-

Brinsea